What is Steam Humidification?

Steam humidification is one of the most common methods used to achieve accurate indoor climate control. Steam humidification units can easily integrate with existing HVAC ductwork, many building management systems (BMS) and offer humidity control without affecting temperature. Steam humidification is a popular choice across a wide variety of industrial and commercial applications.

Steam humidifiers may also be called isothermal humidifiers. Below we will cover the basic kinds of steam humidification and how they work.

Electrode Steam Humidification

Source: Vapac

Electrode Steam humidifiers are a popular choice for buildings in areas with easy access to mains water.

Drinking water contains ions, which allows water to conduct electricity more effectively. Electrode humidifiers provide steam humidification by passing a current between two electrodes submerged in water. Due to the ions present in the water, it will conduct electrons through the liquid, evaporating the water to steam and leaving a chalky residue comprised of those conductive ions. This residue builds up over time, and so these units require regular maintenance to remove and ensure the model is operating at peak efficiency.

The produced steam is then distributed into the target environment via a HVAC ductwork, or can be dispersed directly through a Room Distribution Unit.

This style of steam humidification unit requires only mains water and electricity to create the necessary steam for dispersal. By relying on resources widely available in businesses and buildings this style of steam humidification is a popular choice across many industries and applications. The running costs may prove higher than other options due to it’s need for regular maintenance, but the lower cost per unit plus wide availability, reliability and ease of BMS integration prove attractive to customers.

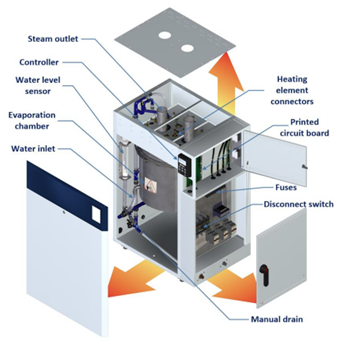

Resistive Steam Humidification

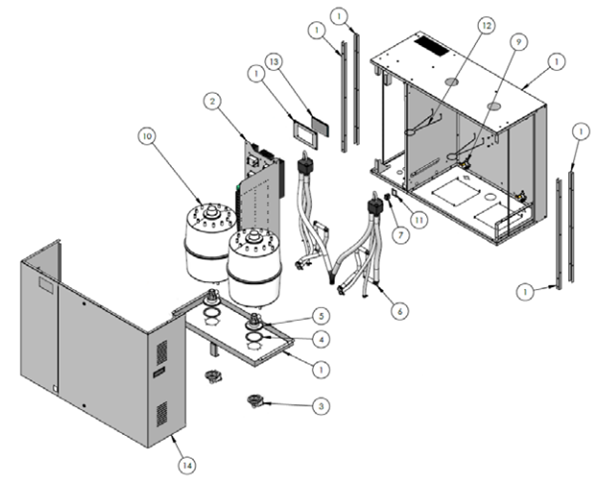

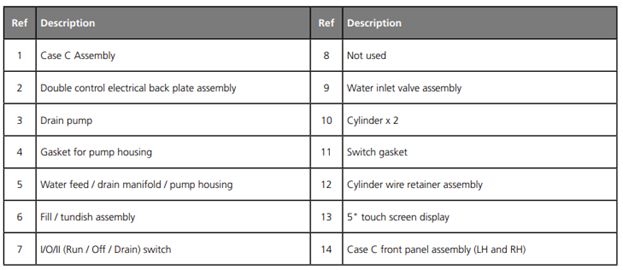

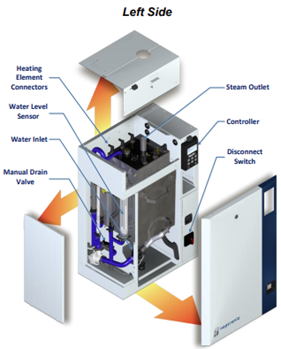

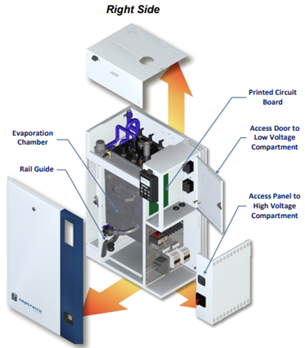

‘Explosion’ diagrams of a Neptronic SKE4 Resistive Steam Humidifier

Source: Neptronic

Resistive steam humidifiers work using technology similar to an immersion heater or kettle. This method of steam humidification relies on a heating element being submerged in water. Heat from this element warms the surrounding water, causing steam which is ready for dispersal. The amount of steam produced depends on the water level, the heat of the element and the temperature of the surrounding area.

This style of model is often used in applications where there is a need for slow and steady steam supply, often over a long period of time. Much like kettles, this form of steam humidifier can suffer from limescale or prolonged usage. One method of preventing this is by using a Reverse Osmosis Water Treatment unit to treat the water, removing ions and other impurities ahead of entry into the evaporation chamber.

The resulting steam can then also be dispersed using the same methods as the steam produced through an electrode unit i.e. through ductwork, or through a room dispersal unit.

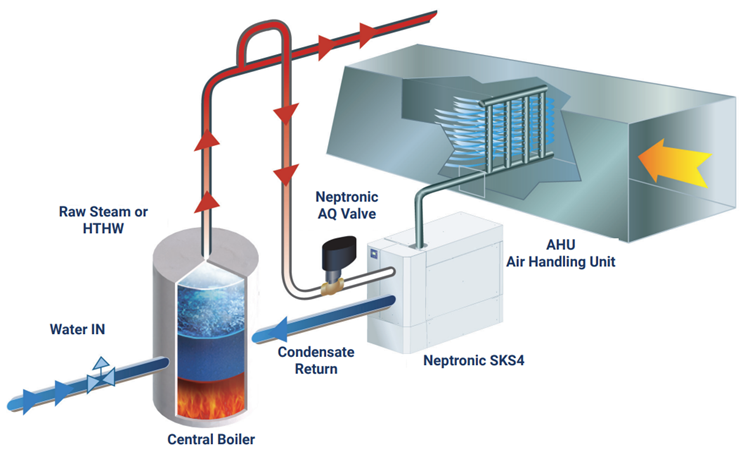

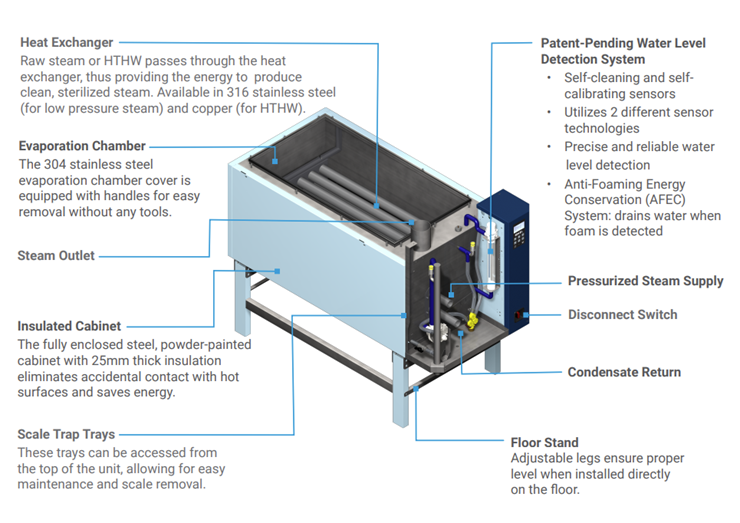

Steam to Steam Humidification

Source: Neptronic

Source: Neptronic

Steam to steam humidification is highly desirable in instances where sterile steam needs to be distributed across a large building, such as in a hospital or care facilities. These models transfer heat from boiler steam to a treated stream of water through a heat exchanger. This relay-like passing of heat from boiler heated steam to sterile water allows for the production of safe, chemical-free steam without the impossible task of regularly dismantling and disinfecting meters of piping. These models are popular in applications where the production of sterile steam is vital, but the area may not have the space for it’s own larger model. These units are also very effective in buildings where there is a steam flow already in place, such as in sterilisation, power plants or water heating.

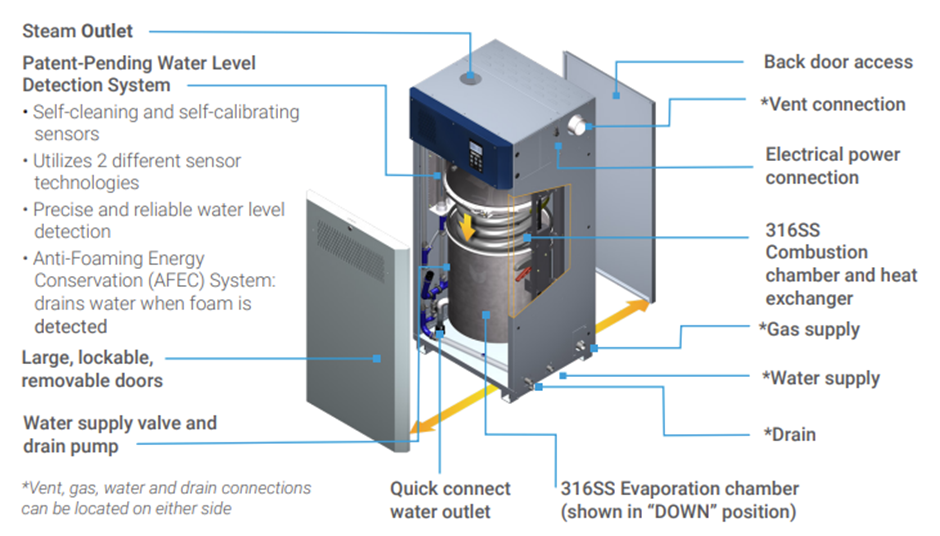

Gas Fired Steam Humidification

Source: Neptronic

Gas-fired steam humidifiers work in a similar manner to steam-to-steam humidification, through heat transfer from hot gas through a submerged heat transfer unit. The heat passes from the gas to the surrounding water, where it vaporises and becomes steam. These units are particularly popular in applications where there is already a reliable access to gas in the building, such as airports.

Gas fired steam humidifiers have exceedingly fast start and finish cycles, allowing agile, responsive humidification on demand. This is particularly useful for establishments controlled by a BMS, where activation and deactivation can be automated according to the building’s needs. The produced steam is often then dispersed through an existing HVAC system.

The waste produced from this form of steam humidification is primarily gaseous, so can be drawn off through a chimney for disposal. Alternatively, the gaseous waste can be channelled through a HVAC exhaust stream to aid in heat recovery and lower overall costs. These units are able to run on any type of water and, due to their responsiveness, can have some of the smallest carbon footprints in the industry, depending on average daily running times and schedules.

Steam Injection Humidification

Source: Neptronic

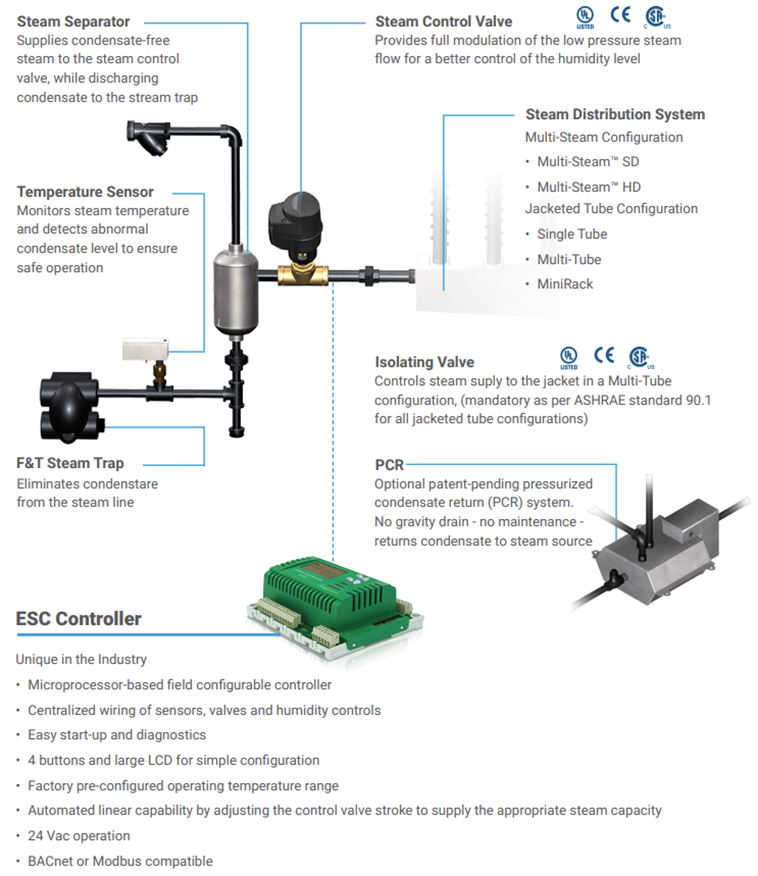

Steam injection humidifiers harnesses steam which is already present in the system, allowing the safe and reliable dispersal of conditioned steam into buildings or the specified controlled environment. Steam produced from elsewhere in the building is filtered to remove condensate, temperature controlled to ensure safety, modulated to control for the desired humidity level and distributed through the chosen dispersal method. These units are especially useful in space-limited systems where noise is a concern. As these units don’t produce their own steam, the initial cost of the unit tends to be lower than their steam-producing counterparts. Due to the direct nature of this form of steam humidification, it is exceedingly responsive and reliable choice.