Discussing challenges in technical fields can feel like swimming through terminology soup. Do you know your hygrostats from your hydrometers? What about the difference between Ultrasonic and Ultradry units?

Never fear. We’re here to help with latter half of our Humidity Control Glossary.

M

Moisture content– The quantity of water contained in a material. This is particularly important in wood processing and often recorded as a percentage.

Moisture meter– Like a humidity meter, but for materials rather than air. These devices measure the moisture content of a material. They are particularly common in wood treatment and processing facilities, but also find use in building sites and vertical farms to measure the water content of concrete and soil.

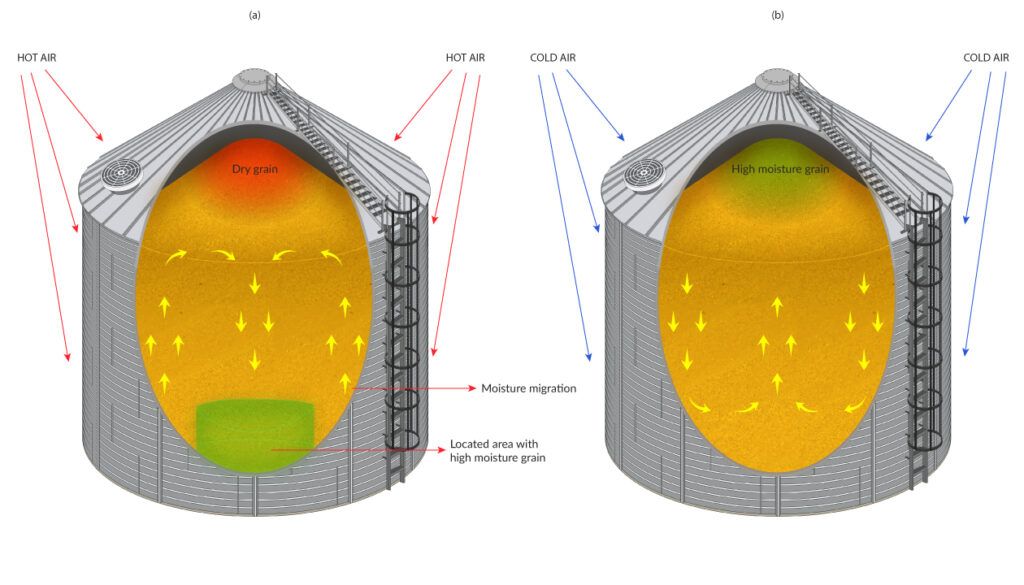

Moisture migration– A complication that occurs in food silos and food storage, moisture migration is the movement of moisture through a space. This process is typically what causes hot spots in grain silos and can lead to mould growth, structural changes with the product and produced quality.

Moisture vapour transmission rate– also known as ‘water vapor transfer’. This refers to the amount of water that passes through a substance over a set period of time, and is often measured in grams per square metre per day (g/m2/day). This factor is particularly important in construction and packaging, where water infiltration can be disastrous to health, safety and product quality.

Molecular sieve– A molecular sieve is a form of desiccant dehumidifier that, unlike it’s counterparts, works well at both high and low temperatures. Molecular sieves are capable of not only taking moisture from the air, but can also acts as a filter, separating molecules based on size and polarity. Due to high consumable costs and it’s small, but precise application, molecular sieves are more suitable for direct dehumidification of a liquid or material rather than full climate control.

N

Nebulisation– The process of introducing water to an air stream through many minute droplets, such as through high pressure or ultrasonic adiabatic humidification.

O

Osmosis– The process of water passing from an area of high concentration to an area of lower concentration through a semi-permeable membrane. The process naturally continues until the accessible liquids on both side of the membrane are balanced.

Osmosis, reverse– A form of water purification used to remove ions and impurities from a water stream. In humidity control, this stream is then fed to a steam humidifiers, allowing more efficient operations and extended the working life of each cylinder. This is particularly useful in areas of hard water.

P

Psychrometrics– The study of the thermodynamic properties of air–vapour mixtures. It is particularly focused on the relationship between air-vapour mixes, temperature, pressures and enthalpy.

Psychrometric chart– Also called a Mollier Chart. This chart depicts the physical and thermal properties of atmospheric air. Each chart accounts for a particular barometric pressure. The standard psychrometric chart assumes the barometric pressure to be the same as at sea level. There are a number of free online resources, such as this one, to help with these calculations.

Q

Quality, Indoor Air– The air quality within structures and buildings. Humidity plays a significant part in improving Indoor Air Quality and preventing Sick Building Syndrome. Uncontrolled, humidity can cause dry throats and skins, increased thirst, tiredness and increased infection rates for transmittable diseases.

Quality control– Humidity control can ensure less flaws and spoilage in industrial processes by preventing changes in the production climate, protecting the final product from unforeseen changes.

R

Refrigerant dehumidifiers– These humidifiers work by passing moist air over a cooled coil, causing condensation to form. This condensate is then drained away, producing dehumidified air. Refrigerant dehumidifiers are most effective in warmer applications, where the cooled coil has a greater contrast to the surrounding environment and can really shine.

S

Sublimation– A state shift where a substance passes from a solid to a gas without becoming a liquid. Humidity control is used to control this process in sublimation printing, preventing spots, blotches and smudging on finished products.

Sorption isotherms– A graph that displays relative humidity compared to the moisture content of a material. These graphs help to approximate and predict the behaviour materials under increasing relative humidifies, but cannot precisely calculate the relationship due to the many factors that influence sorption processes.

T

Target humidity– The humidity level an application is aiming for. Target humidity normally a small range of ±5-10 degrees. Close and more precise applications exist for more sensitive or tightly controlled applications, but often require continuous monitoring and a higher calibre of humidity control unit.

Temperature– A key factor in humidity calculations. Temperature provides an upper limit to the amount of water that can be ‘carried’ in the air. Warmer temperatures also prompt higher levels of evaporation, naturally increasing the relative humidity of a climate.

U

Ultrasonic– Ultrasonic humidifiers are adiabatic (non-heat) units which use a vibrating plate to cause liquid water to vaporise and humidify an air stream. Ultrasonic units produce a cold mist and work well in applications that also benefit from the cooling effect of the mist.

Ultradry– A range of dehumidifiers from Cotes which are designed to support battery production and cleanrooms that require close climate control and dew points under 0oC. The range aims to drive down the energy required to make batteries, incorporating heat recovery, allowing sustainable energy sources to be harnessed and folding in heat pump technology to lower operational costs.

V

Vapour- Refers to water in it’s gaseous form. It is usually recorded in grams per metre cubed (g/m3), relative humidity percentage or in Pascals (Pa).

Ventilation– The V in HVAC. Ventilation can help lower humidity in domestic environments but may not be effective enough to support industrial or commercial applications. Many humidity control units can be incorporated into the HVAC system, allowing air drawn in from outside the environment to be treated before being added to the control climate. When incorporated into an HVAC system, we recommend full HVAC system maintenance as well as humidity control maintenance, ensuring nothing in the system is overloaded or trying to compensate for a weakness elsewhere.

W

Wet bulb temperature– The temperature recorded when the bulb of thermometer is completely wet. This provides the lowest temperature a climate of air can be cooled through evaporation at the current pressure. By comparing this reading against a dry bulb temperature in the same environment it is possible to work out the relative humidity of the area. This is possible through a psychrometric chart.

X

X-Ray– X-Ray imagery is used extensively in quality assurance and product checking. Elements used in Xray tubes are particularly sensitive of high levels of humidity, as is X-ray film, making humidity a key concern for the storage of archived images and maintenance of machinery.

Y

Yield– Humidity control increases yields both in manufacturing by reducing the possible variables in the production process, and is also a key consideration in hydroponics, greenhouses and vertical farms. Vertical farms aspire not only to grow plants, but to provide the maximum output in minimal space, minimal environmental impact and improve food security. Precise humidity control is therefore vital to control the vapour pressure deficient and latent heat in this application.

Year round humidity control– The outside environment is not always stable. Here is the UK we can see a span of environmental conditions throughout the seasons that can be difficult for an HVAC system to compensate for. Humidity control removes that worry, insuring humidity levels inside a climate are steady and reliable all year round.

Yearly maintenance plan– Keeping a humidity solution in good condition is the best way to see a faster RoI, as well as prolonging your unit’s lifespan. We offer regular maintenance contracts, including our popular yearly maintenance service, from a fleet of engineers across the entirety of the UK.

Z

Zone control- BMS (Building Management Systems) are often response for the HVAC and humidity levels of an entire building, not just a singular climate. BMS’ see frequent use in manufacturing, where different rooms may require separate optimum conditions to operate at best efficiency. Zone control can also be used to help increase indoor air quality.

Didn’t find what you were looking for? Find part 1 here.

For more information on how humidity control can benefit your business, check out our Industry pages here, call one of our specialists on 01372 571220 or get in touch through email at info@humiditysolutions.co.uk