An ultrasonic humidifier is a very simple device, consisting of a water reservoir and a vibrating disc called an oscillator. The oscillator vibrates at an extremely high frequency which propels microscopic water droplets into the air. These droplets then evaporate in the air, enhancing the room’s humidity without heating the water. There is no heating of the water at any point, so these humidifiers are sometimes known as “cool mist” humidifiers.

There are many reasons why ultrasonic humidification would be selected over other methods of humidification, and in particular for precision and contamination control. They provide precise control over humidity levels, which is essential in environments where even slight deviations can be detrimental. Maintaining the optimal humidity range ensures a comfortable environment for personnel; enhancing work efficiency, production, testing and offering the hygiene levels required for strict food standards.

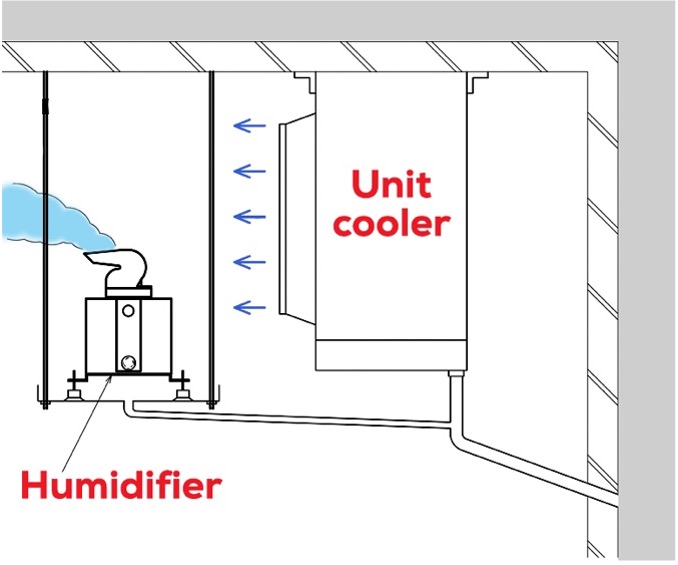

Ultrasonic humidifiers have the flexibility to be installed in a room or a duct. The in-room ultrasonic humidifiers have built-in fans that propel the humidity into the space via an air cushion, so no additional fans or air flow are required. Alternatively, these humidifiers can be seamlessly integrated into existing air handling units (AHUs) using the airflow to carry the humidity around the space, ensuring consistent humidity control without major retrofitting. When a mix of fresh air is brought into these spaces the humidity levels will fluctuate with the seasons. During the colder months, often low levels of humidity are experienced causing inconsistencies in testing, their results and quality from food processing to technology. This type of humidifier can be advantageous due to the fact they are very small and compact which is beneficial when there is a lack of space for large equipment and are often chosen for lower humidification loads compared to other humidifiers. The oscillator frequency can be reduced or increased offering output as low as 0.01kg/hr to 9.9kg/hr and upwards.

Ultrasonic technology is extremely energy efficient compared to isothermal humidifiers, due to the technology it uses which is piezoelectric. This makes it a cost-effective solution, especially for those looking to “decarbonise” and reduce their carbon footprint and reduce energy usage. The ultrasonic process ensures a high level of hygiene, a non-negotiable requirement for applications such as cleanrooms or food production areas. It is essential to incorporate this technology with a Reverse Osmosis unit which complements our other hygiene features such as ultra-violet light and timed water reservoir flushes, as it will not only prolong the life of the humidifier but also ensures that the mist is as pure as possible. The mist will then be free of minerals & impurities reducing the risk of introducing contaminants into the environment such as food production/cleanrooms where contamination control is paramount.

Typical Ultrasonic Humidification Applications:

- Refrigerated Storage

- Clean Rooms and Laboratories

- Plant Germination Rooms & Hydroponics

- Humidors

- Wine Cellars

- Production facilities

- Bakeries

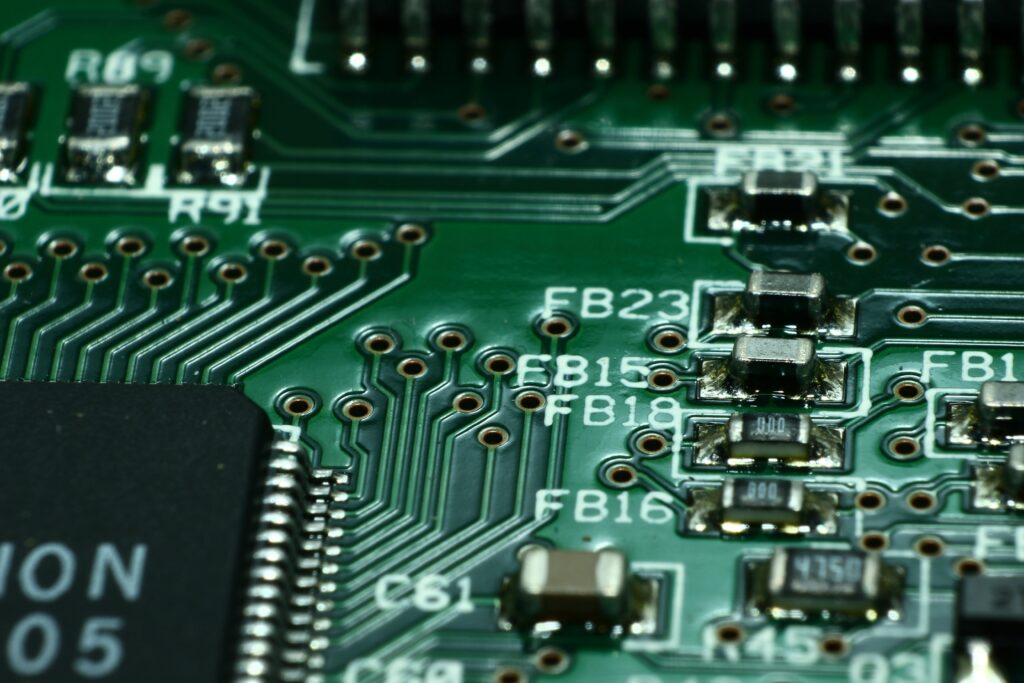

Cleanroom: Circuit Board Manufacturer

Correct humidity levels are vital where sensitive and high-value processes occur, and even minor deviations in humidity levels can result in significant product defects. For instance, low humidity levels can increase the risk of electrostatic discharges and dust particles, potentially damaging electronic components. Humidity levels should be kept typically between 40% and 60% and at the same time maintain a comfortable environment for workers.

Humidity Solutions was asked to provide ultrasonic humidification for an independent, family-owned printed circuit board (PCB) manufacturer specialising in PCB assembly, prototyping and testing, who are recognised for their impeccable test processes, service and the highest quality assembly.

The client was experiencing problems due to low humidity causing electrostatic issues in manufacturing, in turn leading to machine failure and issues with the plastic sheeting storing PCBs to become statically charged. Close control and avoidance of contamination were crucial, as well as maintaining optimal air quality. A steam solution was ruled out by the client due to onsite electrical limits, and ultrasonic became the ideal solution. The technology also offered some beneficial cooling in the space which could often overheat. Thus the ideal environment was created to optimise assembly processes.

Food production: Seed Germination Install

Hydroponics is a method of growing plants without soil by using mineral nutrient solutions in a water solvent. It is an area which requires a very carefully controlled environment to maintain optimum growing conditions.

Humidity control is a critical factor that needs to be considered for indoor growing, for both seed production and salad production in the form of indoor farms. The amount of moisture in the air affects the transpiration rate of plants, which refers to the amount of water lost by plants. Transpiration is responsible for moving water and nutrients from the root to other parts of the plant. However, when humidity levels are too high or too low, transpiration slows and curbs plant growth. The correct humidity level is therefore extremely important – anything outside of this ideal range will cause the stomata to close as a stress-induced response.

Because of our expertise in this area, an indoor farm got in touch with us as they were building a seed germination room for their indoor farm, with the space requiring 95% humidity. Ultrasonic technology was the go-to solution, as the cool mist can be absorbed by the plant’s stomata, increasing the rate of seed germination. Using pure water supplied by a Reverse Osmosis system along with the stainless steel construction of our humidifiers meant we could offer the standards that food production facilities demand.

Ultrasonic humidification presents an ideal solution for many environments, combining precision, efficiency, and hygiene. While energy consumption is vital, choosing humidification technology extends beyond just energy metrics. Ultrasonic humidifiers offer a balanced approach, addressing the specific needs of controlled-contamination environments, ensuring product integrity, and providing a safe and comfortable working environment.

If you would like to find out more about Humidity Solutions’ range of energy-efficient humidity control systems, get in touch with our award-winning experts by calling 01372 571200 or emailing info@humiditysolutions.co.uk