Part of our goal to make humidity control easy is breaking down the science of humidification into manageable pieces. Technical fields are notorious for creating clouds of terminology and it’s easy to get lost in the fog.

Whether you’re a specifier talking about large HVAC projects, or a producer wanting fine humidity control over their cellar, our glossary is here to help outline some of the core terms and concepts you may encounter.

A

Adiabatic- This is a thermodynamic change which involves no heat. Any humidifier or dehumidifier which can operate without the use of steam or heat may be referred to as an adiabatic model. This includes evaporative, high pressure and ultrasonic units.

Air sealing– The process of sealing unintended paths for air movement in or out of a controlled environment. This can be done though chaulking, weather-stripping and other similar processes. Preventing leakage means air sealing can help lower heating and humidity control costs by eliminating untreated air from entering the climate.

Air changes– The number of times the volume of air in the controlled area changes over a set period of time. This value is used to judge the rate of humidification or dehumidification required to keep relative humidity within the required range.

Air velocity – The speed of the airflow through an AHU / Duct / Room. This is vital to be able to calculate the absorption distance of humidification within the airflow, allowing a suitable dispersion method to be selected to avoid wetting from occurring.

B

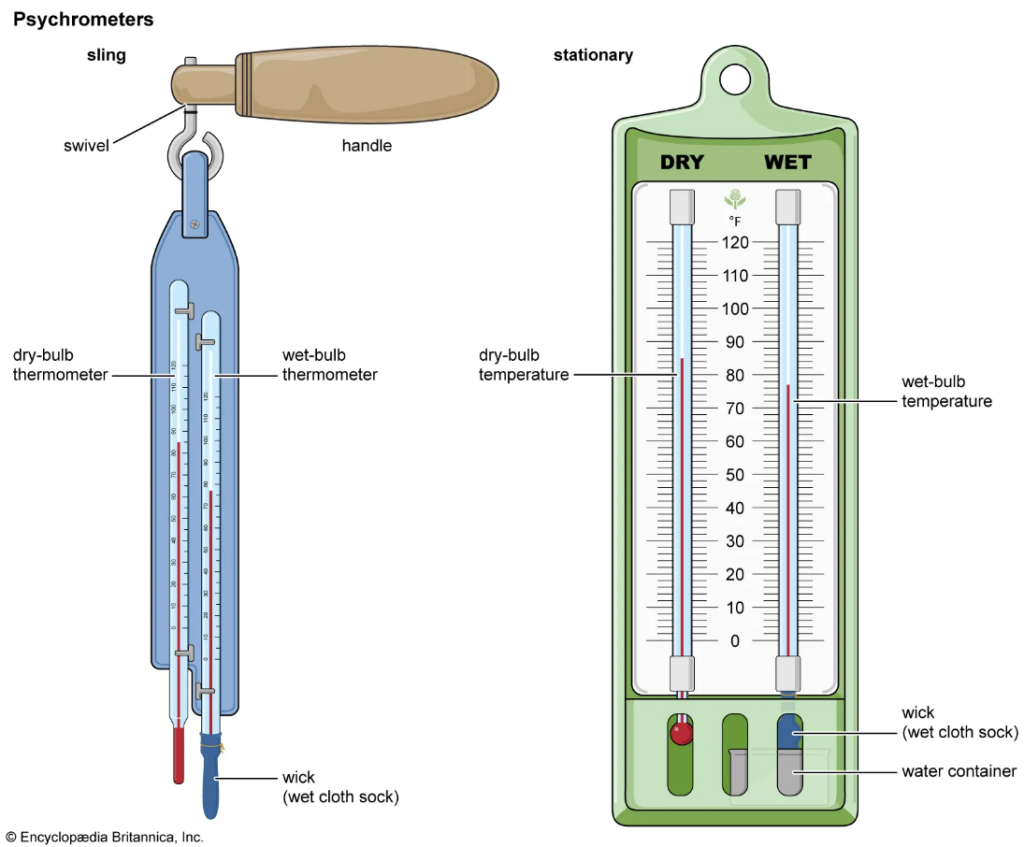

Bulb temperature- Dry bulb temperature is a measurement of air temperature using a thermometer. Wet bulb temperature is the temperature measured using moisture-laden, or wet, bulb in the same environment. This is usually lower than the dry bulb temperature, unless relative humidity is at 100%. When compared the bulb temperatures indicate the state of humidity in the air using a Mollier or psychrometric chart.

BMS– Building Management System. These control systems monitor the electrical systems across a building. This can include climate control such as HVAC systems and humidity control, lighting, security and fire systems.

C

Condenser– This is another name for a refrigerant dehumidifier. Condensers work by passing warm air over a cold surface, which lowers the humidity potential of the air and causes moisture to form. The moisture is then drawn away and drained from the target environment. Condenser, or refrigerant, units tend to more most effective at room temperature or higher, as the presence of a cold surface is vital for optimal unit operation.

D

Dew point– This is the temperature at which water vapour begins to condense into water droplets. At this temperature water droplets collect on surfaces, creating dew. The Dew point of an area can be manipulated through changing the water content in the air and air pressure. This is particularly important in dry rooms and cold stores. The dew point of an area can be calculated through psychometrics and measured through a hygrometer.

E

Exfiltration- The opposite of infiltration, exfiltration refers to the air leaving an environment. In humidity control exfiltration rates are used calculate the air change per hour, and through that work out how much moisture needs to be added or removed to maintain the desired relative humidity.

Evaporation- The vaporisation of a liquid becoming a gas below it’s boiling point. Evaporation is a natural process which increases the humidity of an environment. The energy removed through this endothermic process causes evaporative cooling.

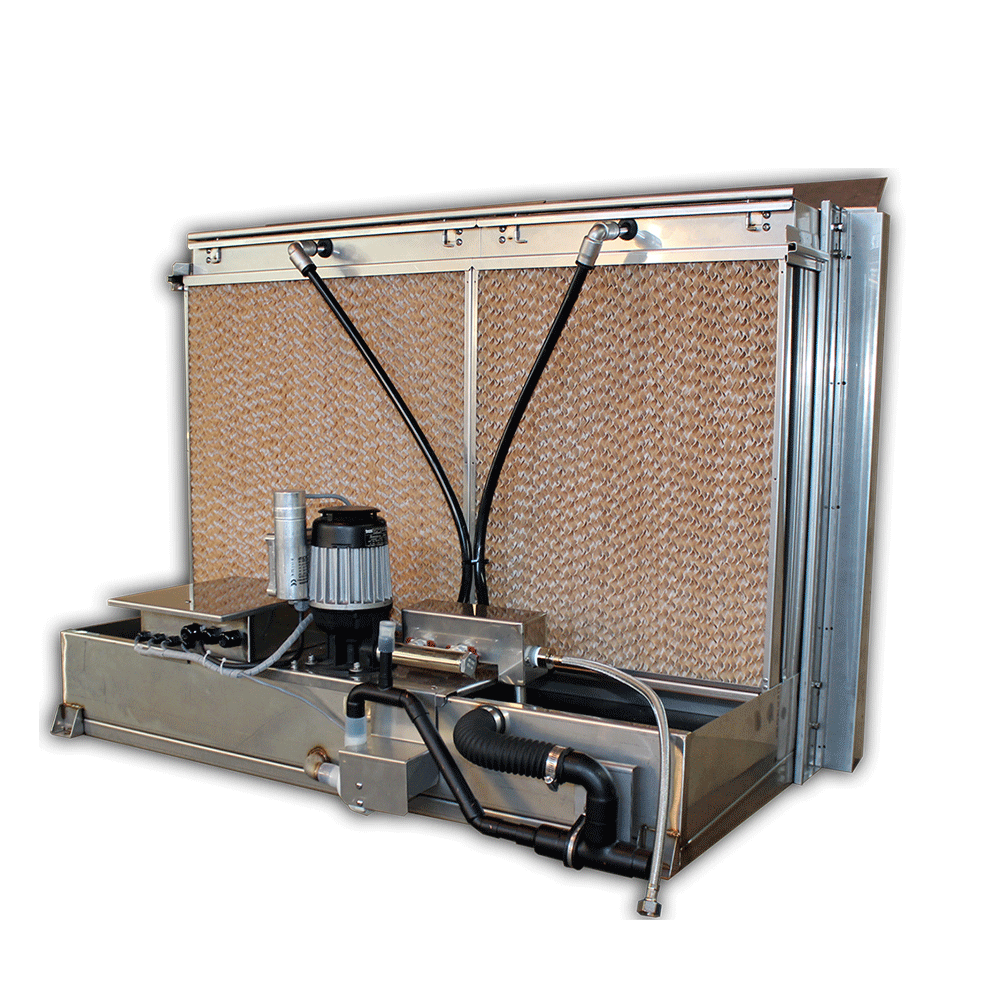

Evaporative coolers- One of the most common forms of cooling, evaporative cooling naturally increases the humidity level of an environment and lowers temperature. Evaporative coolers use water-saturated mediums to increase the surface area of water exposed to an air stream, causing a greater rate of evaporation, humidification and cooling than would occur organically. This units are sometimes called swamp coolers. This units are often more cost effective than air conditioning counterparts of similar strength. They are particularly effective in dry and arid environments, but struggle in areas which already have a high humidity.

F

Flash Point Analysis– Often a concern in laboratories, the flash point is the lowest temperature a substance can produce enough vapour to ignite, which is essential in safety testing. These tests are heavily reliant on temperature within a controlled climate to assess the flammability and volatility of materials. These tests require the incremental manipulation of temperature, which in turn, requires very close humidity control. This both ensures the reliability and validity of test results that may industries rely on.

Fresh air- Fresh air in humidity control is a significant element when calculating the strength and size of a unit required for an application. Fresh air is typically untreated, and must be controlled to prevent it affecting the controlled climate. Fresh air can be introduced through foot traffic, open doors and windows, HVAC systems and foot traffic.

G

Gas fired- Gas fired humidifiers are powered by heated gas rather than electricity. Hot gas is passed through a combustion chamber, where heat from the resulting exothermal reaction is transferred to water to create steam.

Geothermal- A thermal-based renewable energy source, geothermal energy sources are being increasingly adopted to provide cooling and heating for industrial and residential buildings. As an energy source focused around hot water and steam, geothermal energy plants are particularly vulnerable to corrosion and long-term wear. They benefit massively from dehumidification, which extends machine life, decreasing downtime and preventing the need for costly repairs.

Galvanic corrosion- This corrosion occurs when two or more electrochemically dissimilar metals are joined together. This causes the more reactive of the metals to oxidise or corrode, presenting a significant threat in construction and building. This process occurs more quickly in areas of high humidity and can be slowed through direct dehumidification.

H

Heat index – The Heat Index combines air temperature and relative humidity to calculate what a climate feels like from a human perspective.

Humidity – The amount of water vapour in an area. Reliant on air temperature, atmospheric pressure, pollutants, surface temperatures, air flow, people, humidity affects the thermal comfort and air quality.

Humidity, Absolute- The total mass of water vapour held in a specific area or volume of air calculated. Frequently measured in g/kg, or kg/kg. This can also be called volumetric humidity.

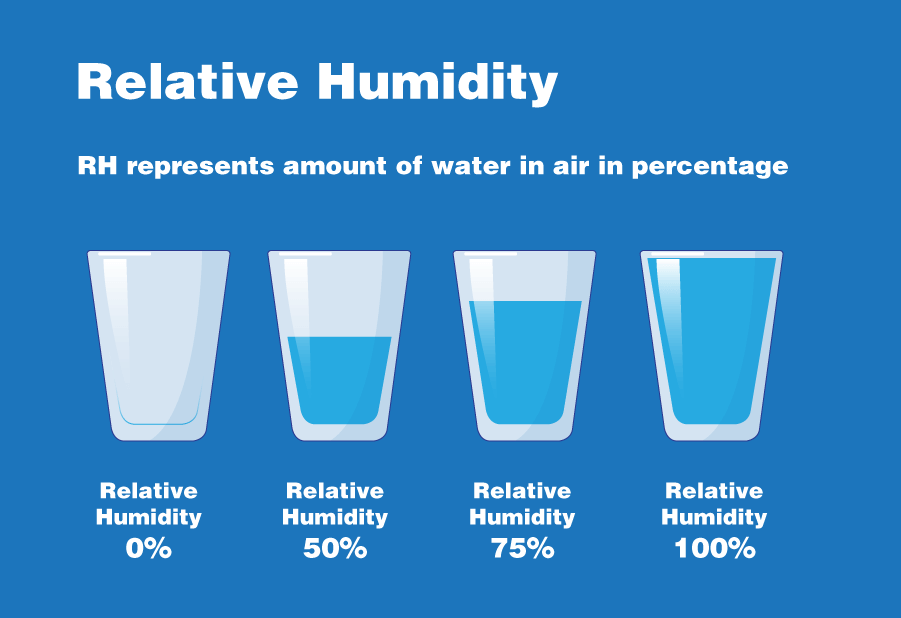

Humidity, Relative- A comparative between how much water vapour is present in the air in comparison to how much it can hold at a specific temperature. This is often measured at a percentage, e.g. 50%RH states that, at the given temperature, the air is ‘holding’ half of the water vapour it can at full capacity. As the percentage increases, so does the ratio of water vapour contained in the area.

Humidity, Specific- The total mass of water vapour compared to the total volume of dry air in the given area. Frequently measured in g/kg.

Humidity Meter- A humidity meter is typically a portable, hand-held device which measure the humidity levels of an area. A common fixture in our site visit and service team kits.

Humidistat- A humidistat acts as a controlling factor for many humidifiers and dehumidifiers. This device monitors the humidity levels of the surrounding environment and allows attached units to modify their output based on the readings. These are often mechanical, with electric variants being known as hygrostats. These are typically wall mounted or duct mounted.

Hygrometer- A hygrometer is a device used to measure the moisture content of the air and compares it against the amount it potentially could hold at the given temperature. These devices typically take a wet bulb and dry bulb temperature and compare the two. The resulting percentage is the relative humidity of the environment.

I

Isothermal- Isothermal refers to any thermodynamic process which occurs at a sustained temperature. In humidity control, this term is often used in reference to steam humidifiers, which change the humidity of a set area without changing the temperature of the controlled environment.

Steam humidifiers come in two main types, resistive and electrode. Find more on steam humidification here.

J

Jewellery- Jewellery displays benefit significantly from control humidity, protecting precious metals from corrosion. Opals, pearls and amber can dry out, causing cracks and chips as the structure becomes weakened, ruining lustre and damaging durability. Conversely, opal, turquoise and emeralds can become discoloured or clouded when subjected to high humidity. To prevent these complications many jewellery show rooms deploy precise humidity control as well as temperature control.

K

K value– the K value of a material indicates its thermal conductivity. The lower a K value is, the better the insulation of the material. Some metals with a high K values, such as gold or graphite are particularly sensitive to temperature changes, meaning their manufacturing areas require climate control in a different manner to ensure precision and reliability in the final product. Humidity control allows tighter control over the amount of water vapour in the air without increasing or decreasing temperature in operations such as battery production, circuit board recreation and pharmaceutical production.

Kw– Kilowatts, a measurement of electrical current.

L

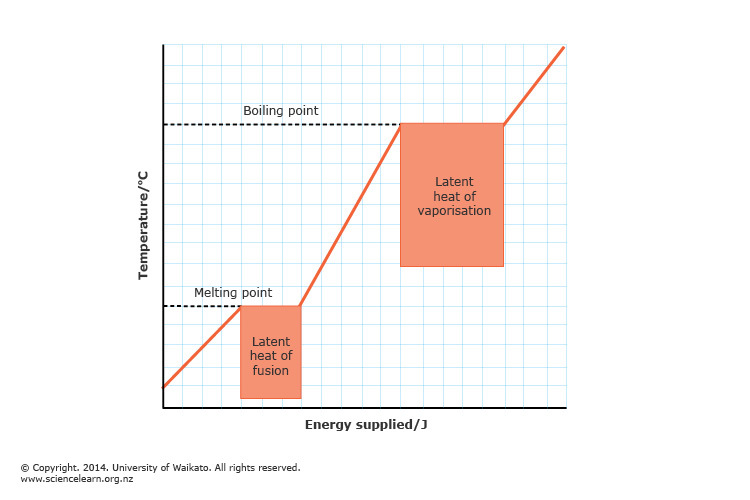

Latent heat– Something of a misnomer, latent heat isn’t actually heat. It refers to the energy absorbed or released by a substance when it changes state during a constant temperature process, such as condensation or melting.

Leakage– Leakage refers to the unintended airflow within a room or structure. Caused by gaps around doors, windows and other entryways, or between joining materials. A room with a high level of leakage will require a much great amount of humidification or dehumidification to control the internal climate, and will struggle to meet close climate control needs. Leakage can be resolved through air sealing.

Humidity control is a complicated niche. As an environmental factor it touches on almost every industry, and can be harnessed to improve operations, lengthen machinery lifespans, enhance working conditions and even drive down costs.

Part of harnessing humidity is understanding it’s impact on you, your industries processes and your health.

If you have any further queries, or want to learn how humidity affects your business, you can find more across our industry pages, get in touch with our specialists at 01372 571200, or email at info@humiditysolutions.co.uk.