Humidity control via an industrial dehumidifier is vital in so many businesses, across a wide variety of business sectors, including charcuterie, storage of classic cars, valuable artefacts, pharmaceutical manufacture and much more. The need for dehumidification is wide-reaching and the applications are varied.

But choosing the right industrial dehumidifier solution isn’t that simple. It takes specialist knowledge and skill to select the correct dehumidifier – with either desiccant and refrigerant technologies – for each project.

Desiccant Dehumidification

Unlike refrigerant dehumidifiers, desiccant industrial dehumidifiers will operate at a much lower temperature, meaning they will continue to extract moisture from the air even in very cold and sub-zero conditions.

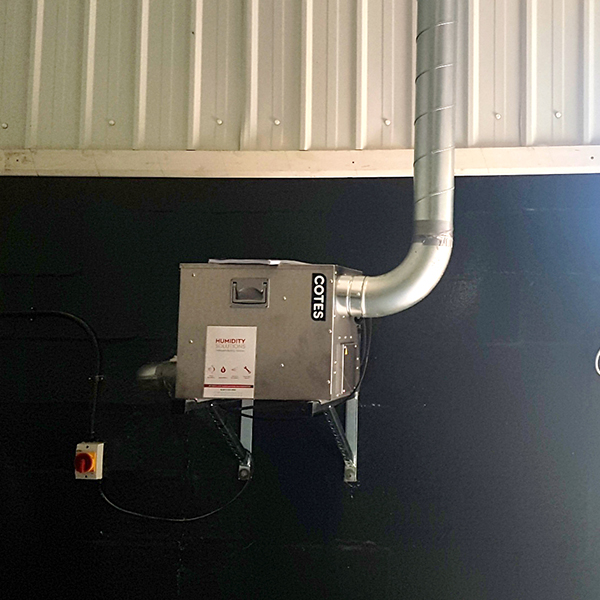

Desiccant dehumidifiers use a silica gel desiccant rotor to remove moisture from the air and are ideally suited to cold, unheated environments. Applications include areas such as storage facilities and cold rooms, where the temperature can get as low as -10⁰C. This technology stops the humidity from dropping moisture onto the cooling coils and causing them to ice up. One area this would benefit is the manufacturing of lithium-ion batteries. Lithium-ion battery manufacturers require ultra low humidity in order to protect the components.

Just like with refrigerant dehumidification, desiccant dehumidifier units are available in a wide range of sizes, in permanent and semi-permanent installations, to provide a solution for all scenarios.

If you would like to find out more about our Desiccant Dehumidifier range, click here.

Refrigerant Dehumidification

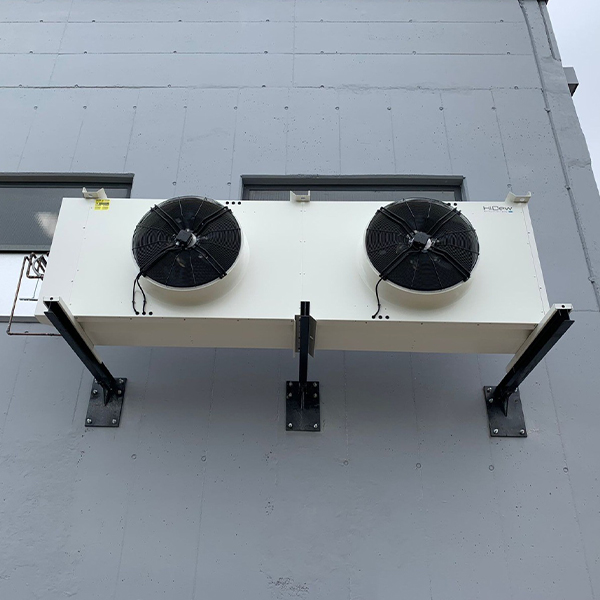

A refrigerant industrial dehumidifier draws in air and passes it over a cooling coil, dropping the temperature to below its dew point. You can achieve extraction rates between 25 and 3000 litres per 24 hours, depending on the size of the unit. This can be drained using either a fitted condensate pump or drained out via duct work. Some units can be placed on castors for portability, but are more commonly fixed wall mounted models, or fixed bracket ceiling mounted versions. There is even a through-the-wall solution available, which means they can be fitted in pretty much any environment.

Other positive features of the refrigerant dehumidifiers include:

- Sound-proofed compressors, meaning low operating noise

- Easy access panels for simple maintenance

- Coated internal components, which can withstand aggressive environments

This opens up a huge variety of different applications for a refrigerant industrial dehumidifier, including warehouse storage, protection of artefacts, swimming pools and much more. However, refrigerant dehumidifiers can’t operate at anything below 1⁰C – for this, you will need a desiccant dehumidifier instead.

If you would like to find out more about our Refrigerant Dehumidifier range, click here.

Investment vs Reward

Investing in a humidity control system will come at a cost in any scenario. But in almost all cases the savings and benefits will end up paying for itself.

The protection of rare books, priceless artworks and documents is essential to preserve value for individual investors or national/global organisations. Indoor trampoline parks, swimming pools and ice rinks all require humidity control. An industrial dehumidifier will prevent mould, odours or the unwanted dripping of condensation from ceilings. Water on the floor is a health and safety issue, and could be an expensive mistake to fix. In food processing or storage areas, dripping condensation might carry bacteria into or from the food product. This can lead to more serious health and safety issues.

Storage of documents, which could be on paper or on film, need to be kept in the best possible condition. Film can turn brittle and be unreadable if the environment isn’t kept within tightly controlled parameters. Without the appropriate humidity control cooling coils, cold rooms might frost up, using extra energy and impacting the operation of machinery, which has a knock-on effect on productivity, cost and quality of product.

Maintenance Commitments

Of course, every piece of machinery requires some level of maintenance. Once installed, dehumidifiers will need routine maintenance, including changing filters to ensure airflow through the unit is maintained and no pressure drops occur.

We generally recommend a planned maintenance programme for all dehumidification solutions, as this ensures you get the best quality of service from the equipment, with minimal disruption. And while you might view it as an unnecessary expense, repairs when something goes wrong, along with any potential losses to your business, will be much more expensive. For example:

Over time, the air filters in your units become dirty, and the fans have to work harder to push the air through the dehumidifier. This takes more energy and creates more wear on the fan and fan motor, shortening its operating life. Unchecked, the system also becomes less efficient at generating the precise conditions required, resulting in a deterioration in production or the climate trying to be created as time progresses. If left still even longer, the airflow could eventually cause the fan to stop or overheat which creates an equipment failure making the situation critical with loss of production or control of the humidity.

Typically, an emergency call-out will cost more than a planned maintenance visit, so it will save you more money in the long run to plan your maintenance. We understand that humidity control isn’t always necessary throughout the whole year for many sectors, which is why we adjust the timing of our visits to reflect your requirements.

Remote Monitoring

If a planned maintenance contract isn’t quite right for you, an alternative is to opt for remote monitoring. This is where the maintenance company monitors the units from their own offices, and provide maintenance only when needed. For example, the unit may trigger an alert saying that the pressure drop across the filters has started to increase, or that the operational hours run above the recommended level, or a fault code has been activated. The maintenance company will be notified, and they can take the appropriate actions.

The required actions might be as simple as a phone call instructing a restart, or sending a service engineer to fix the issue. In this case, the service engineer already knows what the issue is, and can come prepared with the appropriate equipment and parts. And because alerts are often set to sound before the dehumidification system actually fails, everything is kept running efficiently – saving you time and money while still maintaining the humidity control you need.

For more detail on any of the information above, or to discuss your own requirements, please contact one of our specialists by calling 01372 571200, or email info@humiditysolutions.co.uk.