An evaporative humidifier works by harnessing the natural process of evaporation and is a popular choice for energy-conscious manufacturers who need constant humidification with a low running cost. Also called swamp coolers, these units allow users to lower temperature and raise relative humidity in a select space by passing water over a moisture-laden surface.

Evaporative cooling humidifiers work to expand the total surface area exposed to the channelled air, promoting evaporation without the need for an expensive process of heating water or louder ultrasonic vibrating plates. Because the water used does not need to be stored and can be drawn directly from the water mains, there is a reduced need for expensive water treatment before use, allowing for a simple antibacterial and anti-microbial step rather than the need to de-ionise the water supply.

The evaporative media used in these models can become damaged by air purities, dust, extreme water pH and organic materials present in the air passed through the media and left behind.

Maintaining Evaporative Media

Damaged and worn media will require replacing periodically to prevent a loss of efficiency, increased static pressure (which leads to increased running costs) or a slowed rate of supplied air. How often this replacement needs to happen varies depending on water hardness, air purity, hours of uptime use, ambient temperature and other factors. Depending on these factors, evaporative media can last anywhere between several months to several years. Regular maintenance checks can ensure your evaporative unit is working at optimal efficiency.

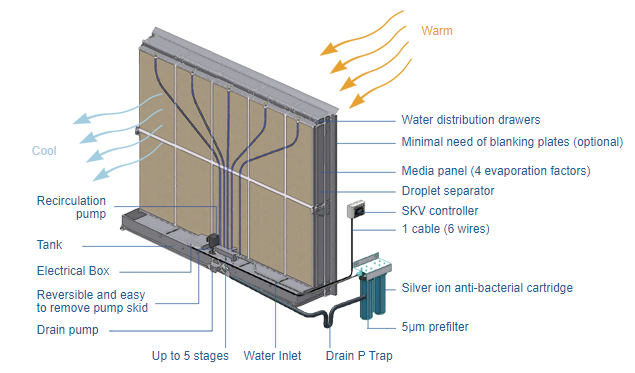

The process of changing evaporative media is every bit as simple as it’s use. Our friends at Neptronic have put together this excellent video explainer for users and maintenance personnel using one of their popular models, the SKV evaporative humidifier.